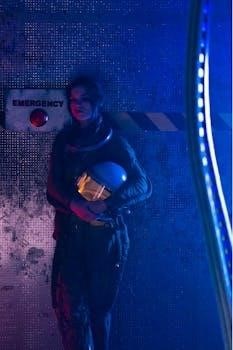

Emergency lights are essential for safety during power outages, guiding occupants to exits․ When these lights fail, it’s crucial to identify and resolve the issue promptly․ This guide provides troubleshooting steps to diagnose and fix common emergency light problems, ensuring functionality and compliance with safety standards․

Common Reasons for Emergency Light Failure

Emergency lights, though designed for longevity, can fail due to several reasons․ Battery failure is a primary culprit; batteries degrade over time, losing their capacity to hold a charge needed during outages․ Faulty wiring and loose connections disrupt power flow, preventing the light from activating․ Bulb or LED failure, whether due to burnout or damage, is another common issue that can stop a light from working․

Damaged components, such as the PCB control gear, which monitors power and charges the battery, can also cause malfunctions․ Power outage issues themselves, including tripped fuses, can prevent the lights from operating․ Obstructed sensors, if present, may hinder the light’s activation․ Finally, a lack of regular maintenance, including testing and component replacement, contributes to failures․ Identifying the root cause is the first step in effective troubleshooting․

Battery Failure and Degradation

Battery failure is a prevalent cause of emergency light malfunctions․ Emergency lights depend on batteries to provide power during outages, but these batteries degrade over time, reducing their capacity to hold a sufficient charge․ Most emergency light batteries are sized to barely meet performance requirements when brand new; as they age, their performance deteriorates until they can no longer operate․

This degradation is a natural process, influenced by factors like usage frequency, temperature, and the battery’s chemical composition․ Regularly testing the battery’s charge-holding capability is crucial to identify degradation early․ A battery failing to maintain its charge or exhibiting signs of swelling or corrosion should be promptly replaced․ Rule of thumb on batteries is five years, because batteries can die and cause emergency light issues․

Faulty Wiring and Connections

Wiring issues can significantly impact the functionality of emergency lights․ Inspect the wiring connections between the battery, charging circuit, and the light itself to ensure proper electrical flow․ Faulty wiring and connections can often cause emergency lights to malfunction․ Look for any loose, frayed, or damaged wires that may disrupt the circuit․ These issues can prevent the battery from charging correctly or impede power delivery to the light when needed․

Repair or replace any damaged wiring to restore proper functionality․ Remember that working with electrical wiring can be dangerous․ If you’re not comfortable or experienced, consult a qualified electrician to avoid potential hazards․ Also, make sure the bulb is tightly connected and that your wire nuts aren’t loose․

Bulb or LED Failure

A non-illuminating emergency light could simply be due to a burnt-out bulb or a failed LED․ These components have a limited lifespan and can degrade over time, causing them to stop working․ Check the bulb or LEDs for any signs of damage, such as blackening or breakage․

If the emergency light uses traditional bulbs, inspect the filament to see if it’s intact․ For LED-based lights, examine the individual LEDs for any visible signs of failure․ Replacing the bulb or LEDs is a straightforward process․ Ensure you use the correct type and voltage specified for your emergency light fixture to avoid damaging the circuit․

It is either the batteries or the circuit boards․ If they are incandescent change the units to led․

Damaged Components (PCB Control Gear)

If the battery and bulb are functioning correctly, the problem might lie within the internal components, specifically the PCB control gear․ The PCB control gear is responsible for monitoring the incoming power, charging the battery, and switching to battery power during an outage․ Damage to this component can prevent the emergency light from operating correctly․

Signs of a faulty PCB control gear include the green charge indicator not illuminating even after changing the battery․ Swapping out the control gear can be a bit more complex but is possible in most emergency lights․ If you’re not comfortable with electrical repairs, it’s best to consult a professional․

Consider that the PCB control gear monitors the main incoming power and charges the battery․

Power Outage Issues

While it may seem obvious, a power outage itself can sometimes be the root cause of perceived emergency light failure․ If the lights don’t activate during a blackout, it’s essential to ensure the outage isn’t affecting the entire building or a specific circuit․ Check other electrical devices to confirm the extent of the power loss․

Furthermore, verify that the emergency light is properly connected to a functioning power source․ Tripped circuit breakers or faulty wiring can prevent the unit from receiving power, hindering its ability to charge the battery and activate during an outage․ Resetting the breaker or repairing the wiring may resolve the issue․

Consider that emergency lights are designed to activate during power outages, relying on battery backup to provide illumination․

Obstructed Sensors

Some emergency lights come equipped with sensors that detect ambient light levels or power outages, triggering the activation of the emergency lighting system․ If these sensors are obstructed, dirty, or malfunctioning, the emergency lights may fail to operate correctly, even during a power loss․

Ensure that the sensors are free from any obstructions, such as dust, debris, or coverings․ Clean the sensors gently with a soft, dry cloth to remove any dirt or grime that may be interfering with their functionality․ Additionally, check the sensor placement to ensure it is not blocked by furniture or other objects․

In some cases, the sensors themselves may be faulty and require replacement․ Consult the manufacturer’s instructions or a qualified technician to diagnose and replace defective sensors․ Proper sensor functionality is essential for reliable emergency light operation․

Lack of Maintenance

Emergency lights, like any other critical safety equipment, require regular maintenance to ensure proper functionality․ A lack of maintenance can lead to various issues, including battery degradation, corrosion of electrical connections, and bulb failure․ Without routine inspections and upkeep, emergency lights may fail when needed most․

Establish a regular maintenance schedule for your emergency lighting system․ This should include visual inspections to check for any signs of damage or corrosion, battery testing to ensure adequate charge and performance, and bulb replacement as needed․ Clean the lights and surrounding areas to prevent dust and debris buildup․

Keep a record of all maintenance activities, including dates, findings, and any repairs or replacements made․ Proper maintenance not only improves the reliability of your emergency lights but also extends their lifespan and maintains compliance with safety standards․ Neglecting maintenance can result in costly repairs and potential safety hazards․

Troubleshooting Steps

When emergency lights malfunction, a systematic approach is crucial․ This section outlines troubleshooting steps to diagnose and resolve common issues․ From inspecting components to testing batteries, these steps will help restore your emergency lights to proper working order․

Inspecting and Replacing Defective Components

Begin by carefully removing the emergency light’s front panel to access internal components․ Visually inspect the bulbs or LEDs for any signs of burnout or damage․ If a bulb appears dark or has a broken filament, replace it with a new one of the correct voltage and wattage; Examine the battery for swelling, leakage, or corrosion, which indicate failure and necessitate replacement․

Next, check the PCB control gear, which regulates power and battery charging․ Look for any signs of damage, such as burnt components or loose connections․ If the control gear appears faulty, replacing it may be necessary․ Ensure you source a compatible replacement part for your specific emergency light model․

When replacing any component, disconnect the power source to prevent electrical shock․ Carefully remove the defective part and install the new one, ensuring all connections are secure․ If you’re uncomfortable with electrical work, consult a qualified professional for assistance․

Checking and Repairing Wiring

Wiring issues can often lead to emergency light malfunctions․ Begin by visually inspecting all wiring connections within the unit․ Look for any signs of loose connections, frayed wires, or corrosion․ Gently tug on each wire to ensure it is securely fastened to its terminal․

If you find any loose connections, tighten the screws on the terminal block or use appropriate wire connectors to re-establish the connection․ For frayed or damaged wires, replace the entire wire segment with a new one of the same gauge and insulation rating․ Ensure the new wire is properly crimped or soldered to the terminals․

When working with electrical wiring, always disconnect the power source to prevent electrical shock․ If you are not comfortable working with wiring, consult a qualified electrician․ After making any repairs, carefully inspect your work to ensure all connections are secure and properly insulated before restoring power to the unit․

Testing and Replacing the Battery

A faulty battery is a frequent culprit behind emergency light failures․ To test the battery, first, ensure the emergency light is disconnected from the main power supply․ Then, activate the test switch or simulate a power outage to force the light to run on battery power․

Observe how long the light remains illuminated․ If it dims quickly or fails to light up at all, the battery likely needs replacement․ Use a multimeter to check the battery’s voltage․ A fully charged battery should read close to its rated voltage (e․g․, 6V or 12V)․ If the voltage is significantly lower, the battery is likely degraded․

When replacing the battery, use a compatible replacement with the correct voltage, capacity, and chemistry․ Ensure the polarity is correct when connecting the new battery․ After replacement, allow the emergency light to charge for at least 24 hours before testing its functionality again․

Testing the Bulbs or LEDs

If the emergency light fails to illuminate during a power outage or when the test button is pressed, the bulb or LEDs could be the issue․ Begin by visually inspecting the bulb or LEDs for any signs of damage, such as cracks, breaks, or burn marks․ If damage is evident, replacement is necessary․

For traditional bulbs, a simple continuity test using a multimeter can determine if the filament is intact․ If there is no continuity, the bulb is burned out and needs replacing․ For LED units, testing can be slightly more complex․ Visually inspect each LED for signs of failure․

If individual LEDs appear fine, the LED driver or circuit board might be faulty․ In this case, consider replacing the entire LED lamp head or, if possible, testing the voltage reaching the LED module with a multimeter․ Ensure the replacement bulb or LED unit matches the original specifications for proper operation․

When to Replace the Entire Unit

While troubleshooting emergency lights often involves replacing individual components like batteries or bulbs, there are situations where replacing the entire unit is the most practical and cost-effective solution․ If the emergency light is old and has required multiple repairs, it might be nearing the end of its lifespan․ Repeated failures indicate underlying issues that are likely to persist․

Extensive damage to the unit, such as a cracked housing or corroded internal components, can also warrant a complete replacement․ Similarly, if the circuit board or control gear is faulty and difficult to source, replacing the entire unit might be simpler․

Consider that newer models offer improved energy efficiency and reliability․ Replacing outdated units ensures compliance with current safety standards and reduces the risk of future malfunctions․ Evaluate the cost of ongoing repairs versus the price of a new unit to make an informed decision․

Comments